How to Choose the Best Commercial Ice Maker [Buyer’s Guide]

Posted by CANDY POSA

![How to Choose the Best Commercial Ice Maker [Buyer’s Guide]](http://ozcoolers.com.au/cdn/shop/articles/png_1024x1024.progressive.png.jpg?v=1521164268)

Commercial Gourmet Ice Makers

Gourmet ice cubes are ideal for special occasions, banquet services, and upscale restaurants. The ice not only has its own unique shape, but it will also not dilute the flavor of your drink, at least not as quick as other types of ice on this list. It tends to be very clear to the eye, odorless and melts slowly. Shaped like a small shot glass, this crystal-clear ice has a very beautiful look to it, which is what makes it so attractive for special events.

Ice can take on many different types and shapes. Above, we have shown you six common types and shapes of ice that our machines can provide. Each type of ice has its own particular use. For drinks, you will want to choose something that is slow-melting and avoids diluting the actual flavor of your beverage. For cooling, preservation, or display purposes, choose a type of ice that melts slowly and helps to preserve the hydration of whatever you are transporting, storing, or displaying. Understanding the difference between the ice shapes and types should help you to better use them to their maximum potential.

Sizing Your Commercial Ice Maker

The next step in choosing the right commercial ice machine is to figure out how much ice you'll need in each 24-hour period. Each establishment is unique, and the amount of ice it requires will vary based on many factors, but the following table can help you estimate how much ice you'll need based on the type of business you run.

Ice Machine Formats

Once you've determined how much you'll need your new ice machine to produce, it's time to decide which ice machine format will serve you best. Commercial ice maker machines come in three main formats: head-and-bin combos, ice dispensers, and undercounter ice machines. Your decision will be based on how you'll use your ice day-in and day-out.

Ice Machine Head-and-Bin Combos

I'll use my machine to:

- Serve ice in an entire dining room

- Fill satellite bins located around my facility

- Fill fresh-food displays

An ice machine head and bin combination is the right choice if you're looking for a machine that will provide enough ice for an entire dining room's worth of drinks. The majority of these machines will produce ice in the range of 136 kg to 226 kg a day, while some can produce nearly 907 kg. The bin component of the combo will store a couple kilograms of ice at the ready to be scooped into cups or totes.

A general rule of thumb is to pair an ice machine head with a bin that will hold half to two-thirds of the machine's daily production volume. That's an ideal range because it will help keep you well stocked with ice to handle sudden spikes in traffic. Nothing has the potential to cause panic like a server opening an empty ice bin during a busy Saturday night shift. Most head-and-bin combinations sold adhere to that rule.

An exception to the above rule may apply if your establishment tends to see a good deal of its traffic in short bursts. In those cases, it may be beneficial to choose a combination with a larger bin, one with a capacity large enough to hold an entire day's worth of the machine's production. A large bin may also prove beneficial in venues that host meals only once or twice a week. A church kitchen that's only open on Wednesday and Sunday is one such example.

Undercounter Ice Machines

I'll use my machine to:

- Provide ice to bartenders

- Equip server stations with a convenient source of ice

- Provide smaller quantities of ice for specialty beverages or applications

A smaller alternative to a full-size, head-style ice machine is an undercounter ice machine. These units are designed to fit underneath countertops, so they can be tucked neatly behind bars and server stations where they can give members of staff quick access to the ice they need to prepare drinks. The majority of undercounter ice machines produce from 22 to 136 kg of ice daily. Undercounter ice maker machine bin capacities range from a couple dozen to more than 90 kg of ice.

You may also choose to invest in an undercounter ice machine that will provide smaller quantities of ice for your specialty products. An under-counter nugget ice machine, for example, can give you the ice you need to blend frozen drinks. An under-counter machine that produces gourmet cubes can serve as the ice source for your premium cocktails and liquor served on the rocks.

Ice Dispensers

I'll use my machine to:

- Dispense ice at a self-serve drink station

- Dispense ice at nurse stations in healthcare facilities

For any application where you need to dispense ice directly into cups, pitchers, or buckets without having to scoop it from a bin, you'll want an ice dispenser. Dispensers provide the easiest and most sanitary method of delivering ice from a bin to a cup, making it the obvious choice in applications where guests will serve themselves. Dispensers work well at nurses' stations in healthcare facilities to equip staff to conveniently dispense ice for patients' drinks and to prepare ice packs to treat wounds.

The drawback to using an ice dispenser is that it's slower than scooping ice directly from a bin, and the equipment itself introduces an extra set of mechanical components and their associated upfront costs and maintenance requirements. That's why an ice dispenser is rarely the best back-of-house ice solution.

Smaller ice dispensing units are comprised of an ice machine built into a bin-and-dispenser assembly. Higher-capacity dispensing setups come in the form of separate, modular equipment - a full-size ice machine head and a dispenser and bin assembly. Another option is a standalone dispenser that contains no ice machine. The latter solution will require staff to manually fill the bin from a separate ice source.

A Note on Ice Machine Head and Bin Adapter Kits

If you should opt to purchase an ice machine head and bin or dispenser separately, or if you're replacing one component or another in your existing setup, be sure to choose pieces that can be paired together. Even components from the same manufacturer may not be compatible. Some combinations may require that you purchase a separate adapter kit in order to interface the two parts together. The equipment's spec sheets or owner's manuals can tell you which combinations can be made and whether a particular combination requires an adapter kit. Any head and bin or dispenser combination you order from KaTom will include the pieces need to connect the two components.

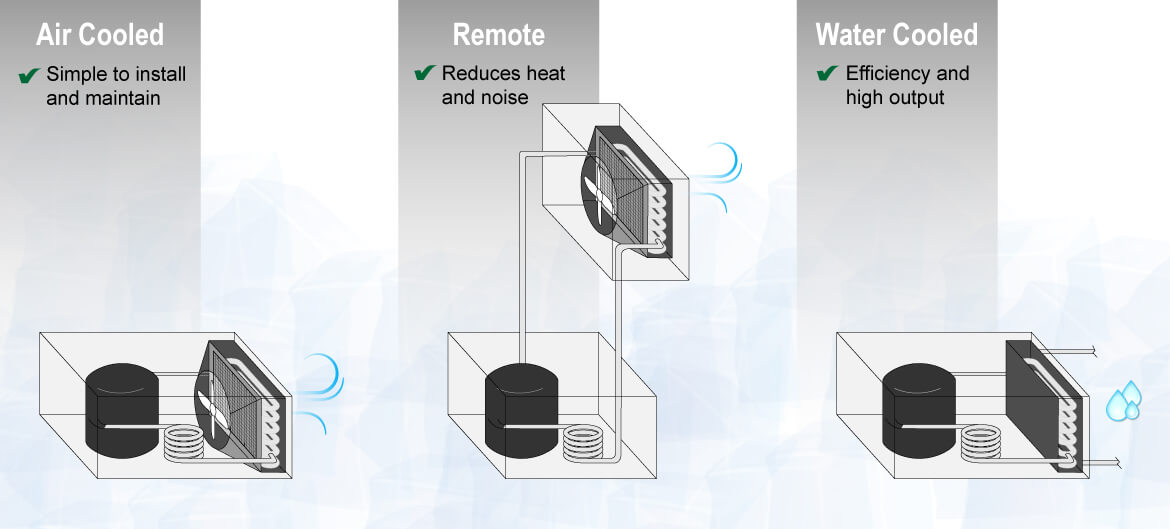

Choosing Between Air-Cooled, Water-Cooled, and Remote-Condenser Ice Machines

One critical component that all ice machines have in common is a condenser. It's this piece that's responsible for ridding the machine of excess heat so it can continue to freeze water into ice. There are three types of ice machine condensers, and you'll need to choose a machine with the one that best matches your venue.

The most popular type, air-cooled ice machines are equipped with fans that move fresh air across their condensers to cool the equipment. These machines are the simplest to install and maintain. The entire condensing unit is contained inside the ice machine itself and requires no additional wiring beyond the machine's main electrical connection. An important point to consider when you buy an air-cooled machine is whether you can accommodate the machine's clearance requirements. The machine may need to be installed with a certain amount of space between it and surrounding objects to receive the airflow it needs to keep running smoothly.

An air-cooled machine is a right choice for the majority of operators, but there are some exceptions. If your machine will be installed in a room where ambient air temperatures regularly exceed 80 degrees Fahrenheit, you'll probably want to consider a machine with a water-cooled or remote condenser. High ambient temperatures will reduce the volume of ice that a machine can produce, and regular exposure to high temperatures can cause a machine to fail.

A popular alternative to air-cooled ice machines is equipped with remote condensers. Instead of being contained within the ice maker itself, a remote condenser is housed in a piece of equipment that is installed in a separate location, usually on the building's roof. The refrigerant is piped from the ice machine to the condenser, where it is cooled and sent back to the machine.

Remote condensers bring a number of advantages, the biggest being that they move the noise- and heat- generating components of an ice machine outside the building. That means that a remote-condenser ice machine won't put an extra burden on your HVAC system like an air-cooled machine will. It'll also help keep the noise level in your establishment down, which can be important if the equipment is placed within earshot of your dining room or bar. This type is especially preferred in large locations with a high number of refrigerated equipment and in hotels, where it can keep the noise and heat of the ice machine out of the guest areas.

The advantages of owning an ice maker machine with a remote condenser come at a higher equipment cost and more expensive installation. However, those costs may be offset by the energy savings and increased ice production that remote-condenser units can bring.

The third category of ice machine is the water-cooled type. As with an air-cooled machine, a water-cooled ice maker's condenser is enclosed within the machine itself. The difference is that instead of blowing air across a condenser to remove heat, a water-cooled machine pumps cool water by the condenser coils to achieve that cooling. This method requires a constant source of cool water in addition to the machine's potable water supply. This requirement makes water-cooled equipment unfeasible for most establishments since it requires hundreds of gallons of water an hour to be sent down the drain.

The establishments that benefit the most from water-cooled ice machines are ones with water-circulating chiller systems that they can tie their ice machines into. Because the water used is typically cooler than the ambient air, these machines are often significantly more efficient than other types, which is why they're generally used to show the highest possible output from a given model. Another product of this efficiency is that this setup is likely to require less electricity.

Clean Water and Filtration

No matter which type or size of ice machine you ultimately choose, you'll more than likely want to connect that machine to a water filter system when the machine is installed.

An ice machine water filter serves several purposes. First it will reduce the concentration of dissolved minerals that make it into the ice machine. These minerals are present in just about every water supply across the country and are in especially high concentrations in areas with hard water. While those are generally harmless to people, they can wreak havoc on ice machines. The ice-making process causes those minerals to be left behind in the form of deposits that build up over time on internal ice machine surfaces. Left unchecked, those will reduce the output and energy efficiency of your machine and can eventually cause the equipment to fail. Although you'll still need to clean an ice machine regularly to remove mineral deposits, a water filter will reduce the number of minerals that get into the machine.

Purer water also freezes faster and creates harder, clearer ice that melts more slowly than ice with a high level of dissolved minerals. That means your machine will be able to produce a higher volume of ice each day and that ice will last longer in your customers' drinks.

A second advantage to installing a water filter system is that it will remove the taste of chlorine from water, giving you a supply of ice that tastes fresh and clean, and won't impart off-tastes and odors to your drinks.

When you choose a water filter system for your ice machine, make sure it's compatible with your equipment. Manufacturers typically offer their own filter systems and replacement cartridges, both of which are sized to match specific models. The ice machine's spec sheet or user manual will tell you which filter or filters you should purchase.

Ice Machine Accessories

Finding a machine that will give you enough ice is just one step in the process of building an efficient ice production system. It's also important that you equip your restaurant crew with the accessories it needs to get the most from the equipment. Here's a list of the essential ice maker machine accessories that you'll likely want to keep handy.

Ice scoops are by far the most common ice maker accessories and they're often the most important. If you have an ice machine with a bin, you'll need an ice scoop on hand to stay compliant with health codes, since it's against the rules to scoop ice directly from an ice bin with the cup you'll be serving it in. It pays to take every precaution possible when it comes to protecting your patrons' health, so choose an ice scoop with guards that will prevent the user's hand from touching the ice.

An ice scoop caddy provides a sanitary way to store your ice scoop in the bin. Health codes prohibit scoops from being stored on top of or in the ice. A caddy mounts to the inside of the bin and helps prevent germs from the user's hands from contaminating ice.

Food codes and general best practices prohibit bottles being stored directly in ice that will end up in drinks, but wine bottle caddies provide a workaround. These accessories mount to the inside wall of an ice bin to separate bottles from the ice while still keeping them cool. This setup also keeps bottles dry and easy to grab from the bin.

You may need a container other than your machine's ice bin to hold fresh ice, especially if you want to serve it at a location where there's no dedicated machine like an outdoor bar. That's where a bar ice bin will come in handy. These stainless steel bins hold several kilograms of ice handy so staff can make drinks and get them to guests quickly without having to run to the ice machine. This equipment is sometimes built with cold plate technology that keeps soda chilled as it's pumped to a soda gun mounted nearby. Some ice bins are equipped with bottle holders that let you keep liquor, wine, and mixers chilled in the ice in a way that the health inspector will approve of.

Staff in certain establishments need to transport quantities of ice from one location to another, such as from the main bin to an auxiliary bin or from the kitchen to a bar. It is in these cases where an ice tote will prove indispensable. You'll find small ice totes to transport as little as 9 kg of ice and large ice buckets to handle a few kilograms of ice. Many of these buckets are equipped with hangers that attach them to the sides of ice bins so they're easy to fill. Ergonomic grips and handles help reduce the chances of staff members becoming injured while handling these containers, and totes are designed to keep germs from employees' hands from contaminating ice.

If you need to transport extra large volumes of ice, look into buying an ice caddy. These mobile, wheeled bins are available in capacities ranging from 22 to 90 kg of ice. They come in handy for transporting ice to off-site events, outdoor bars, and large satellite bins.

Ice machines and bins are designed to empty spent water through a floor drain, but not all facilities and installation locations can provide that utility. If that describes your situation, you'll need to install a drain pump on your ice machine that moves wastewater from the ice machine bin into a suitable nearby drain.

A good number of ice machines mounted on legs, which are almost always adjustable. Adjustable legs allow the equipment to be installed so that water can flow through the machine in the way the manufacturer intended. In the case of nugget and flake machines, a unit that's not installed level will experience uneven wear on its auger bearings and run the risk of failing prematurely.

Selling ice by the bag is a nice way to bring in a little extra profit, especially if you can find a customer base that regularly needs ice, like festival-goers or picnickers. An ice bagger is an investment that can pay off. These systems mount to the side of ice bins and provide a way for staff to quickly fill and tie bags of ice.

As we mentioned above, you can elect to buy ice machine heads and bins separately or shipped together as a combination unit. If you opt to order the two components separately, you may need an additional accessory called an ice bin top kit or adapter kit that will allow the two pieces to fit together properly.

If the amount of ice you need varies from day to day, you may not always need a full bin of ice on hand at all times. This is where an ice level control kit may come in handy. This device allows you to set the maximum amount of ice you need to keep on hand. The machine will shut off once the bin reaches that level. To prepare for a busier daypart, you can increase that level.

Looking for a Commercial Ice Machine?

T : 1300 885 693

E : info@ozcoolers.com.au

W : www.ozcoolers.com.au